Description

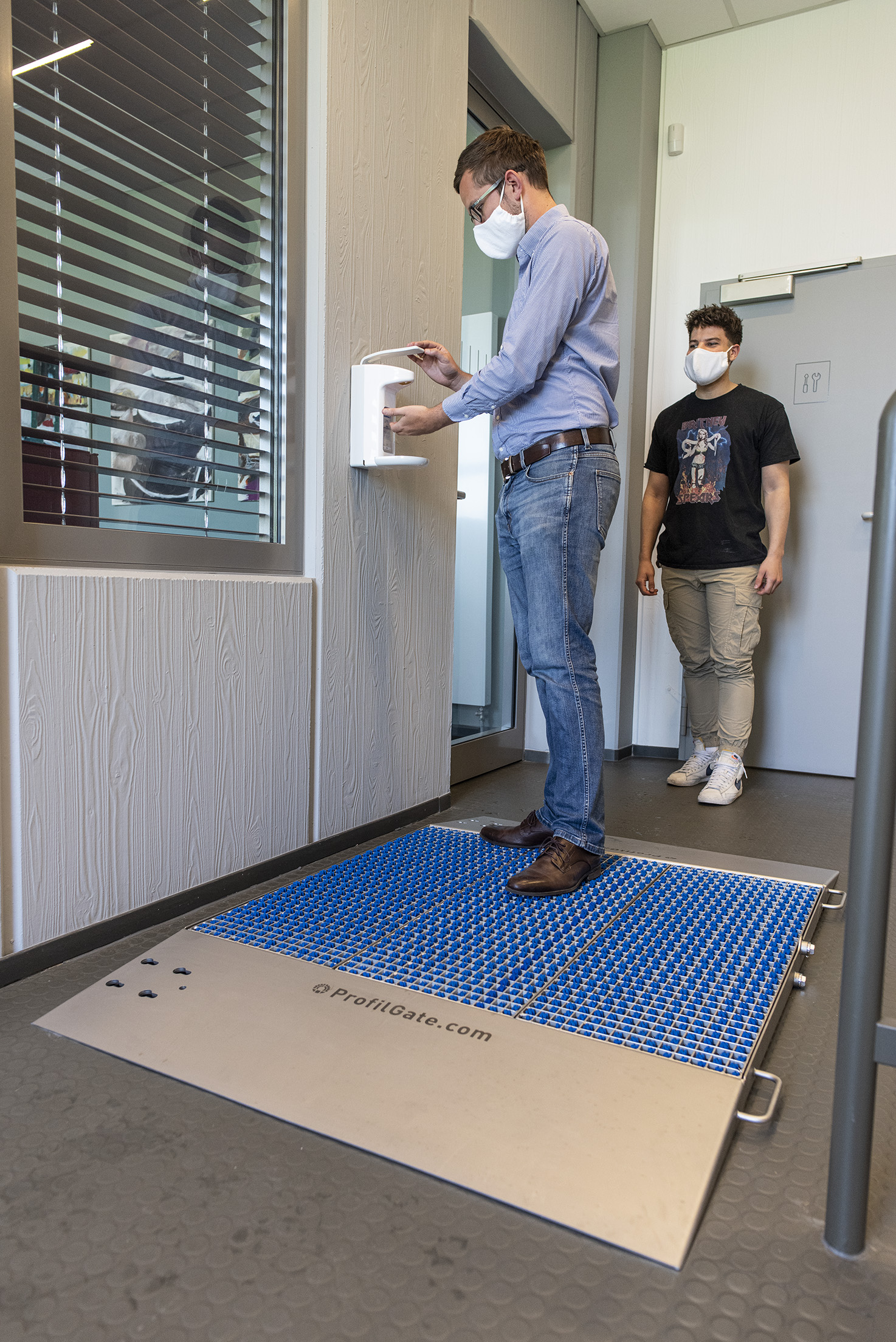

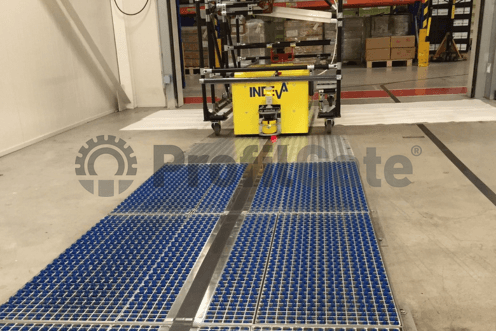

ProfilGate® is a foreign object capturing system which automatically captures glass, metals, stones and soil from the soles of safety shoes and trolley wheels (even soil from forklift tyres).

The root cause of many foreign object contaminants are always found on the floor where they are easily transferred from an outside environment (high risk) into the production or packing floor (low risk). Foreign contaminants (metal shavings), office (staples) or even glass or soil from a production line can easily end up into products. Even detection systems (metal and X-ray detectors) may not pick up small sized objects (<2.0mm) such as staples or a sliver of glass.

And the worst thing is that just one foreign contaminant (glass or metal) can result in product recalls. The phone calls to customer (Woolworths and Coles!), the calls to regulators, the media and even your manager or CEO. It goes on and on for days and weeks.

Up until now, the only way to capture contaminants is using a cleaner who sweeps the floor and uses vacuums to suck up small particles. It’s costly and inefficient as they normally include this as one of many other tasks they perform during their shift.

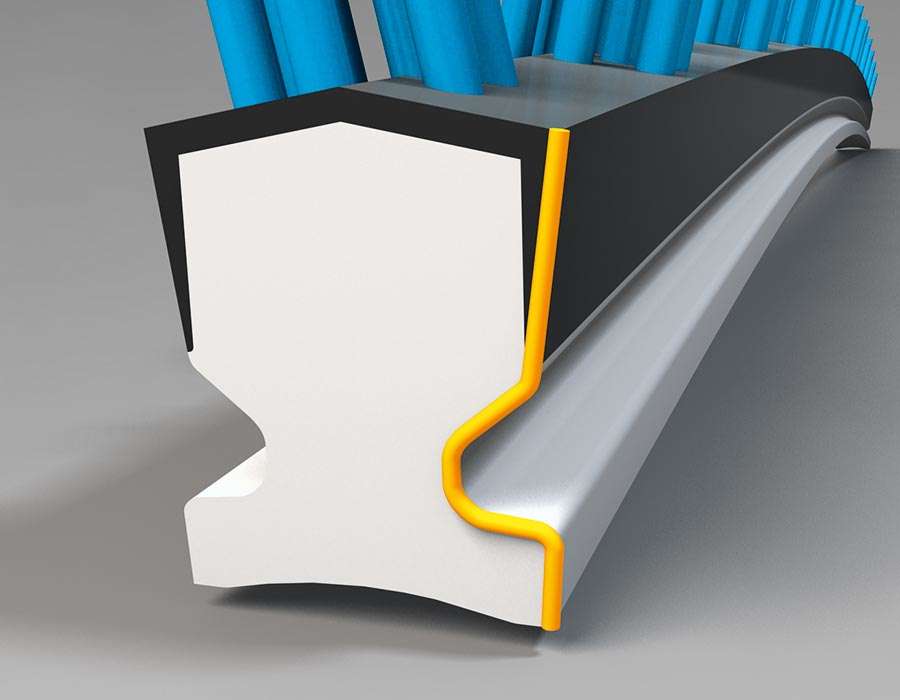

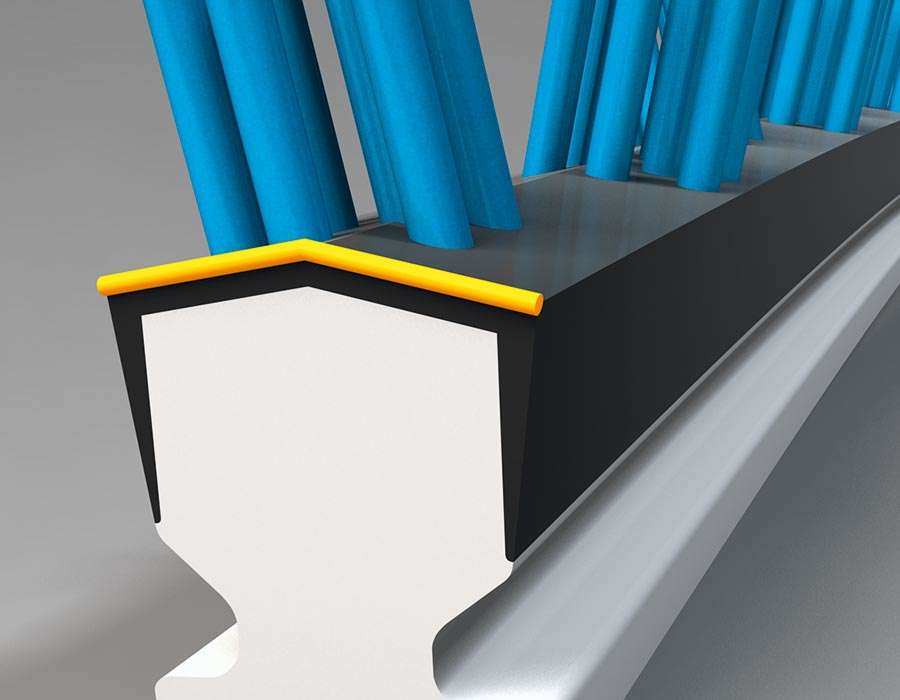

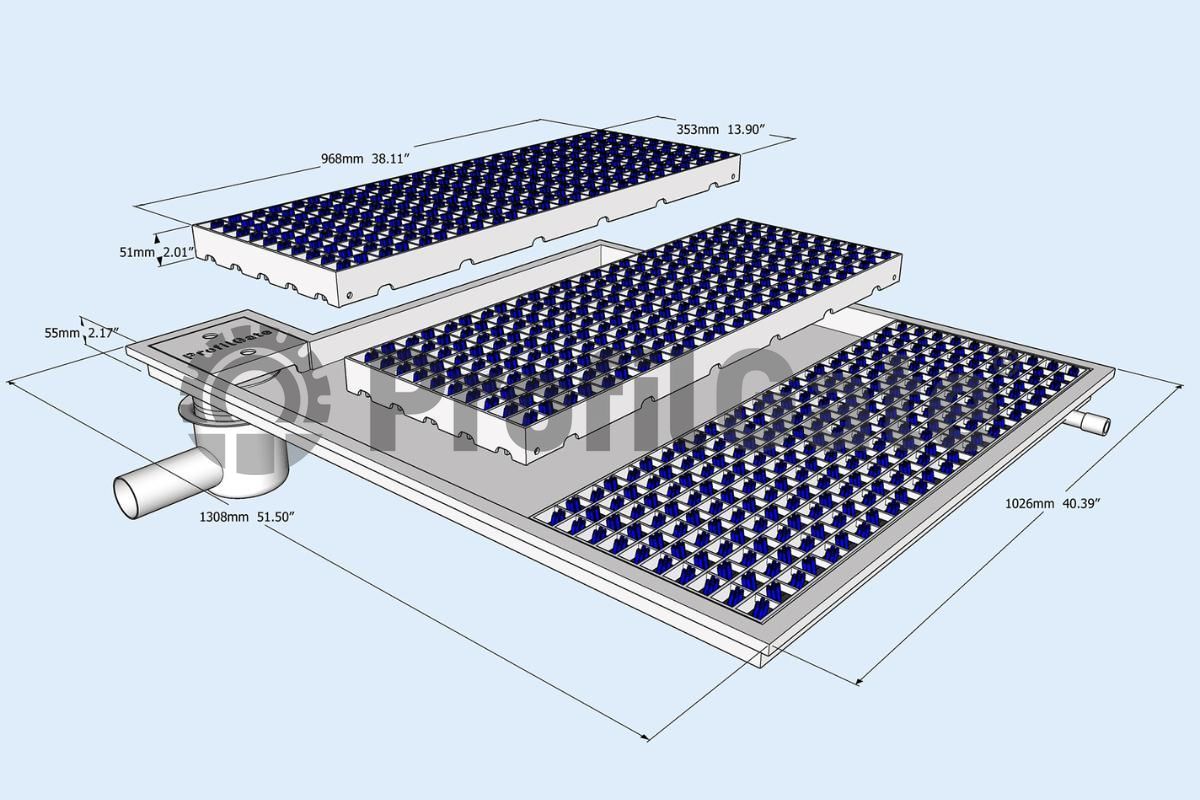

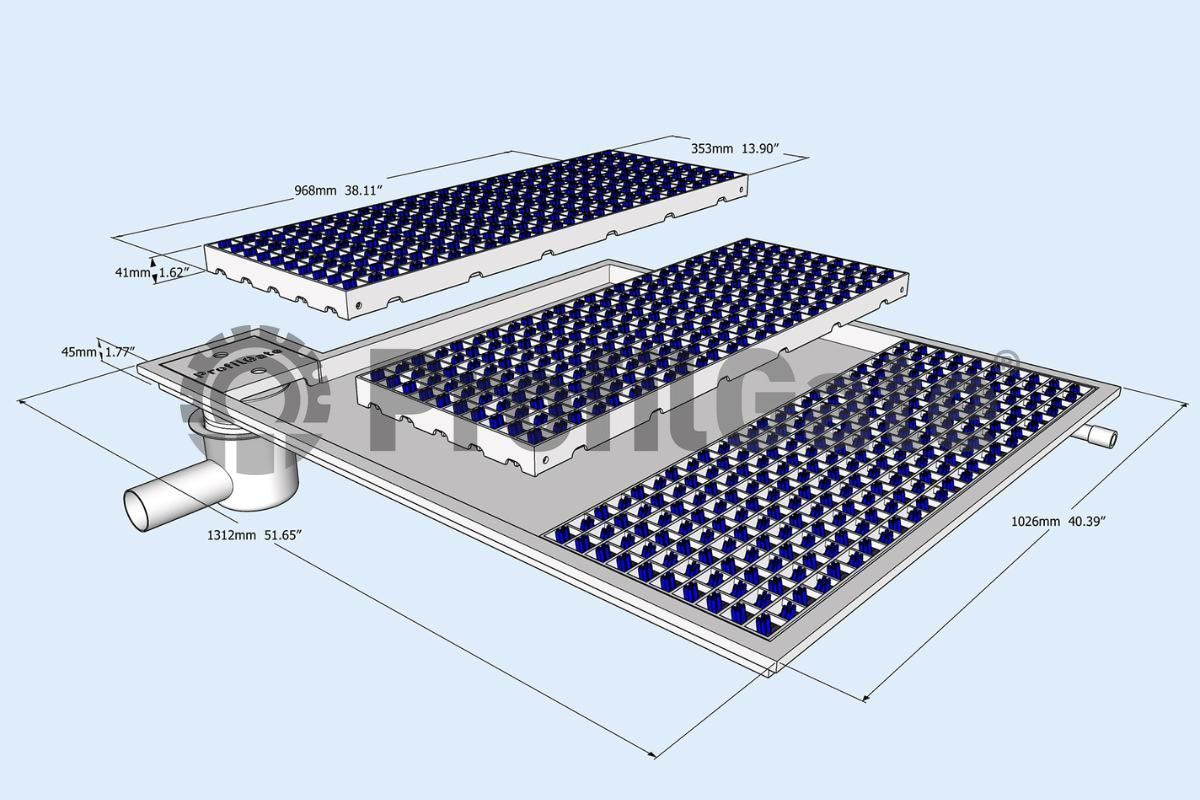

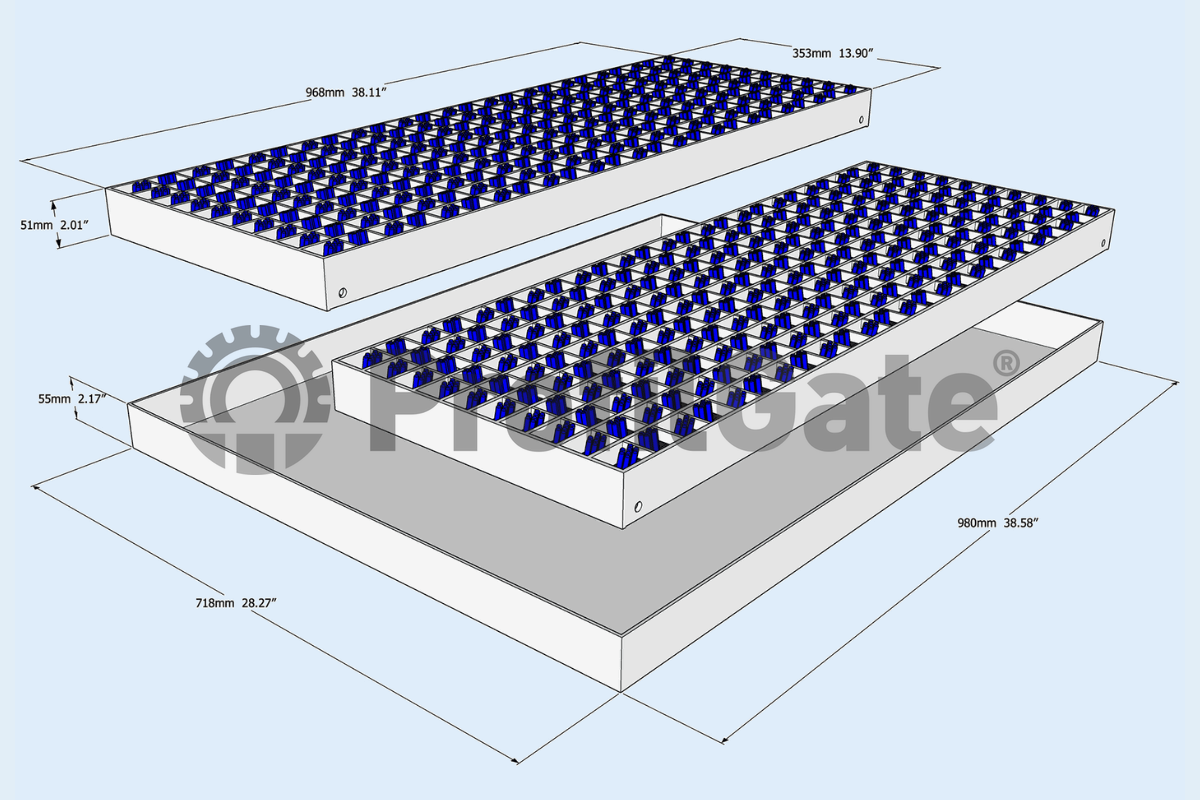

The Profilgate is a patented capturing system introduced in 2010 from Germany. The system captures all foreign objects through traffic movement 24/7 and besides emptying out the captured soil, it’s virtually maintenance free. It consists of a stainless steel capturing tray, metal grid and special capturing brushes angled with specific hardness, height and angle to remove the soil upon contact. Everything is captured into the stainless steel tray 24/7, 7 days per week.

Perfect for warehouse entrances, production floors, maintenance entrances and so forth. The system is used by Automotive industries such as Audi, Porsche, Volkswagen and Opel. In the beverage industry it is used by Bavarian Breweries and in Dairy by Friesland Campina– the world largest dairy co-operative. https://www.youtube.com/embed/eBFyuFhPvEE

It can be mounted at ground level or above ground level and be accessed via flat ramps. This way a forced passage can be set up easily which all vehicles have to pass.

Hot-dipped grates with special brushes are placed inside stainless-steel bins, which collect the brushed off dirt. The particular angle of the special brushes automatically clean all kind of tire treads mechanically when crossing the grates. Electricity is not necessary.

6 Goods Reasons for ProfilGate®

Improved cleanliness, better quality and reduced maintenance cost are some of the many advantages of ProfilGate®.

Your company can demonstrate its customers, suppliers and legislators that it is willing to improve cleanliness beyond the regulated hygiene and safety requirements.

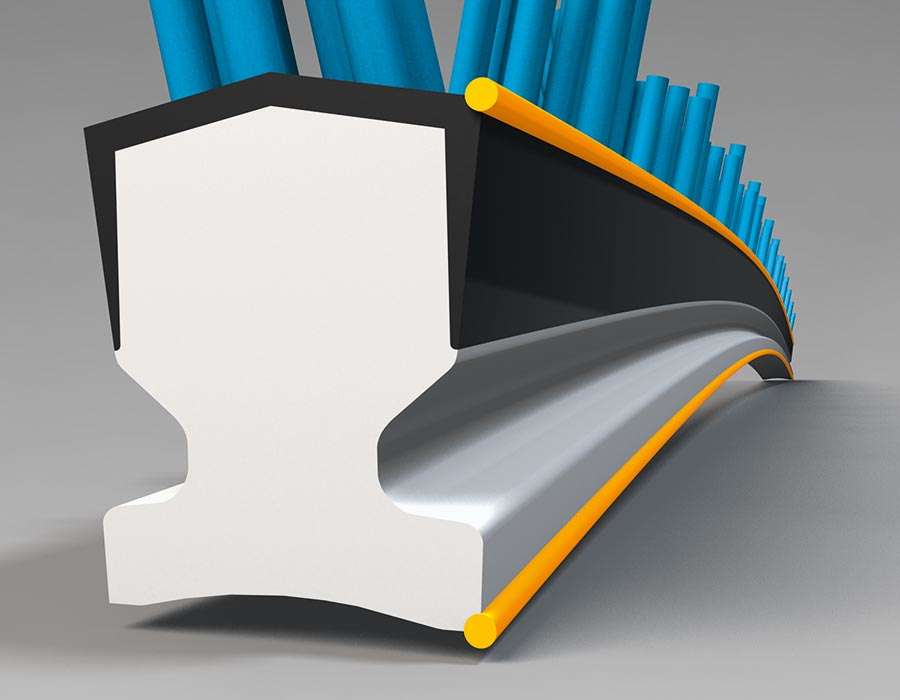

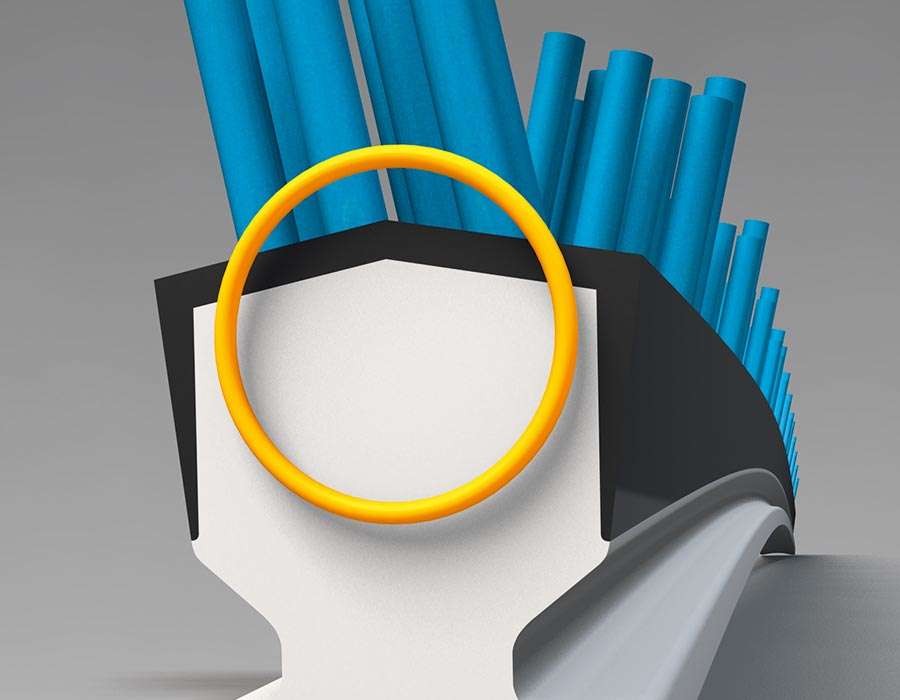

The technology in ProfilGate®

The Difference is in the Details

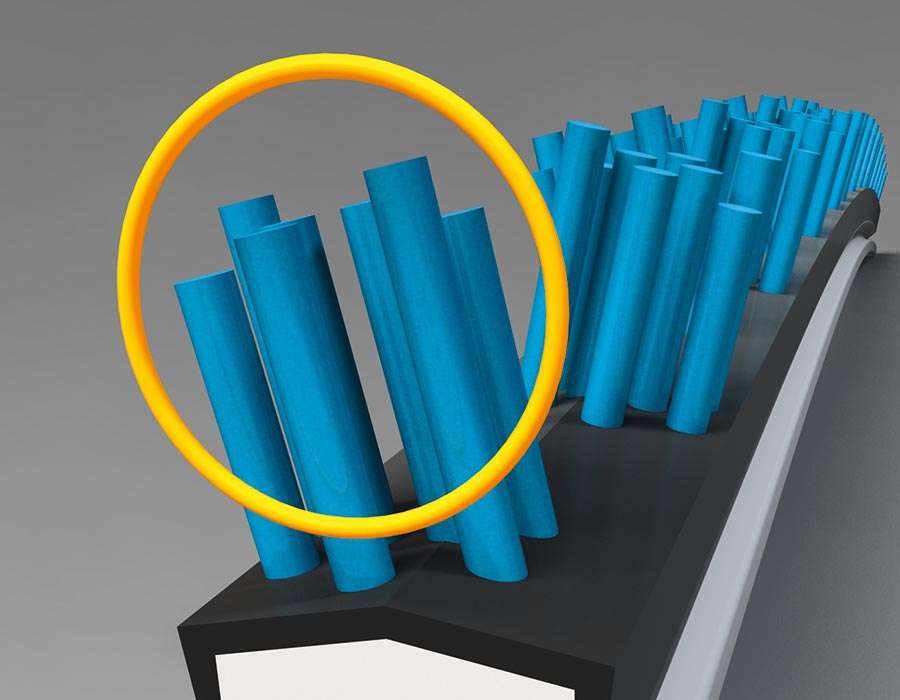

The patented brush strips are the core of the innovative ProfilGate® system.

Due to ongoing improvements and further development, the sophisticated brushes guarantee highly efficient cleaning of driving and walking zones. A large combination of detailed engineered functionalities assures optimum efficient cleaning results, smooth operation and longevity. The sustainable design requires no electricity.

Application for ProfilGate®

The application of ProfilGate® is particularly suited to industries and companies, which…

- have high traffic movement (more than 20 passages per day).

- use vehicles to move goods into facilities or from less critical areas into areas requiring a higher degree of cleanliness.

- wish to reduce actual cleaning cost.

- consider technical cleanliness to be essential for the quality of their products.

- want to reduce their occupational health and safety risk, by keeping the floor dry and avoiding wheel-borne contamination.

- need to prevent germs and bacteria from being spread by personnel or vehicle movements.D7

ProfilGate® helps nearly all sectors and industries to solve problems that occur due to dirt transmission. It perfectly supports the implementation of several 5S programs as well as the TPM system (Total Productive Manufacturing).

Clean Factory Interactive

The Clean Factory shows the optimal areas of application of ProfilGate® in clean factories. The patent system automatically cleans tread surfaces of tires, wheels, wheels and shoe soles purely mechanically when driving over. The concept of the Clean Factory clearly shows how the introduction and carry-over of dirt is extremely reduced by using the various ProfilGate® models. Technical cleanliness thus simply becomes a question of method.

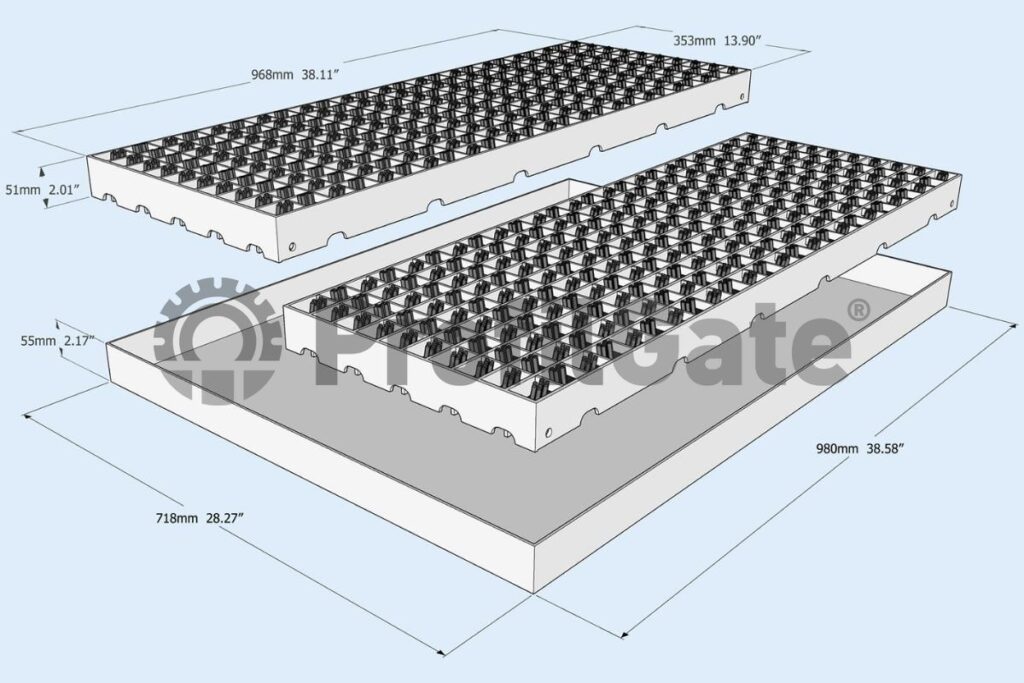

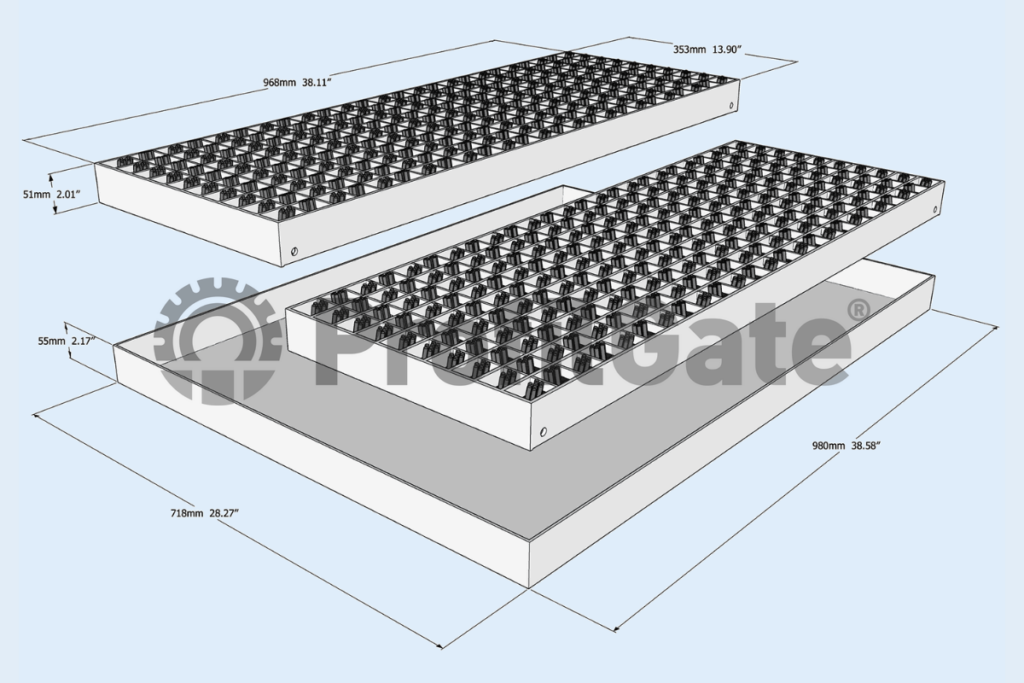

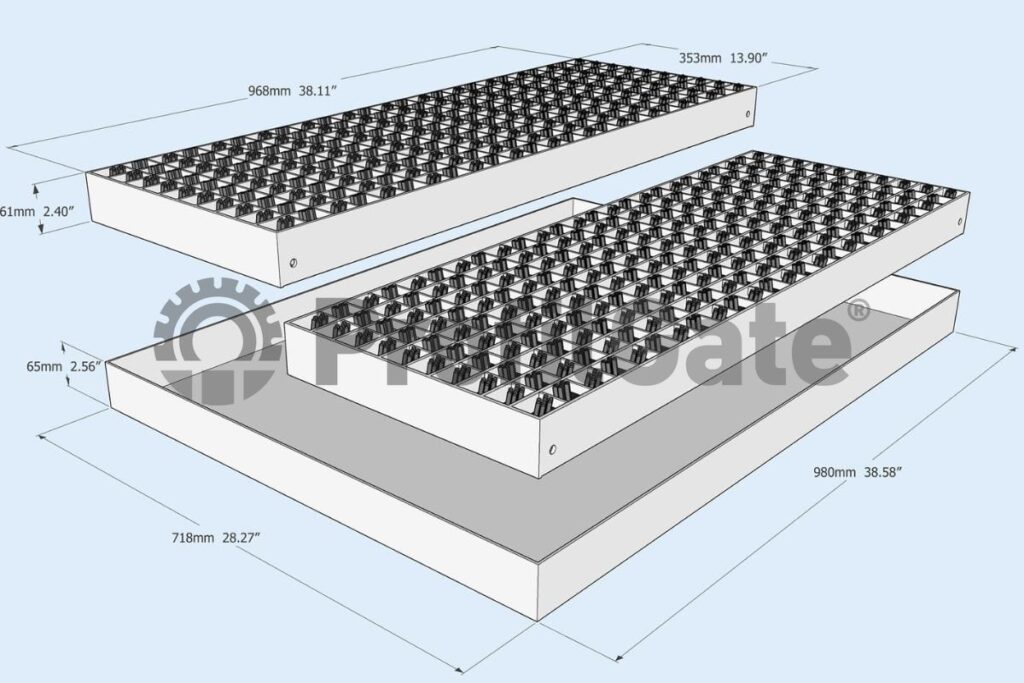

ProfilGate® models:

Download the ProfilGate® Brochure

ProfilGate® models:

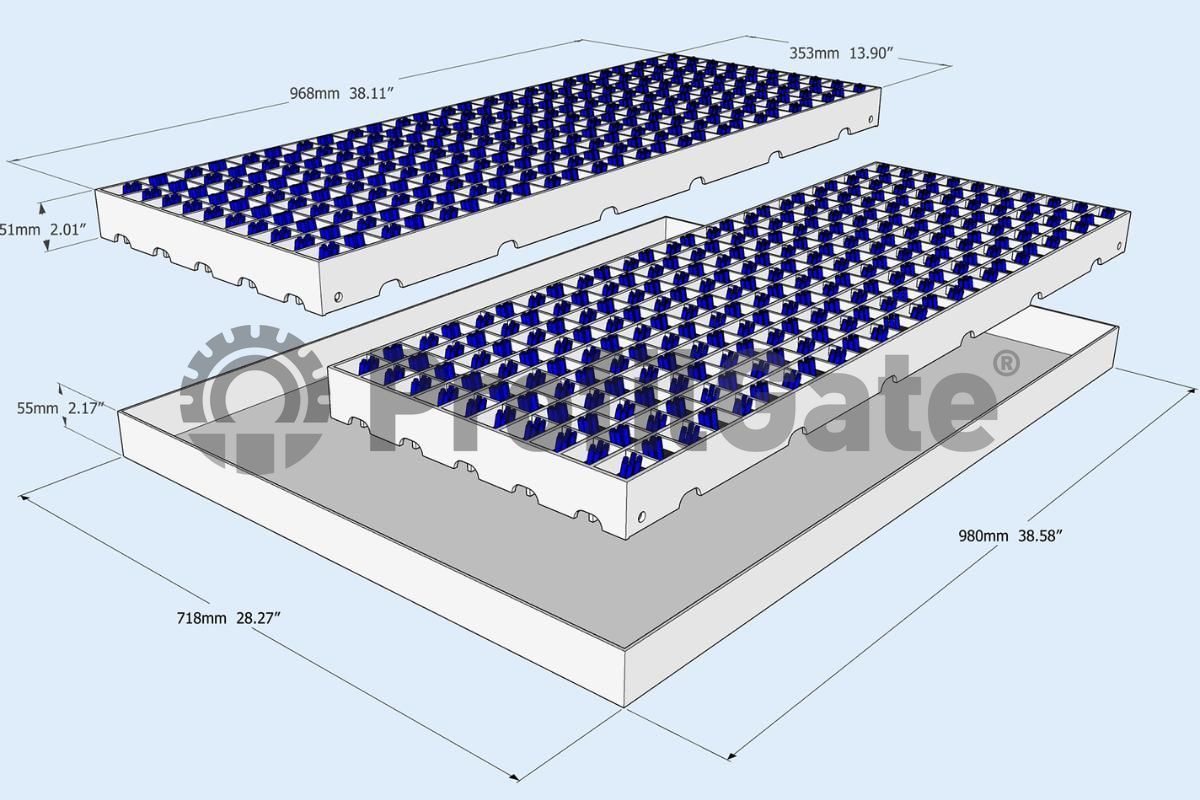

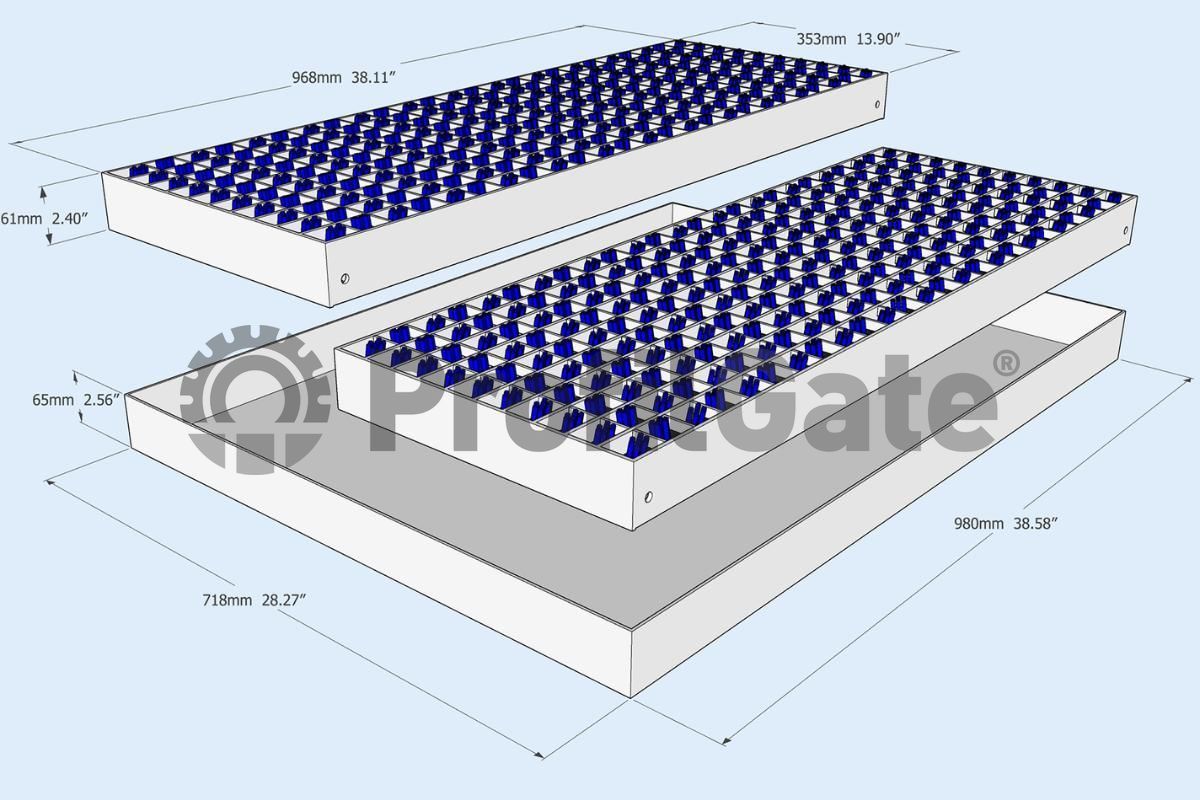

The models of the ProfilGate® b Series are ideally suited for driveways from outdoor areas. Due to high dirt absorbing volume and wide-mesh grates, they are especially suitable for the cleaning of wide tires, rollers and wheels with high axle loads and load-carrying capacities.

Ideal for facility entrances from outside due to the high dirt absorbing volume and wide-mesh grates. Especially suitable for the cleaning of coarsely profiled soles.

The i-models are ideally suited for food, pharmaceutical and chemical industries, where dealing with moist and wet environments and aggressive cleaning agents is necessary. The ultra-smooth surface of the grates ensures a quiet operation of hard casters and wheels of handcarts and trolleys.

Ideal for entrances from outside areas due to the high dirt absorbing volume and wide-mesh, stainless-steel grates. Especially suitable for coarse contaminations. ProfilGate® go has been developed specially for active sole cleaning in an industrial environment. The long bristles clean working shoes with coarse profiles reliably and consistently.

The clean zones of the i-aqua series are designed for wet cleaning and disinfection of tires, rollers, wheels and shoe soles. The material is rustproof and therefore ideal for areas with high hygiene requirements, such as those in the food industry.

This portable system is for sanitation of shoes and wheels with stainless steel ramps. The system will have the dosing and waste on the one side only. The fine-mesh, special-steel grates enable low-vibration passage of industrial trucks with narrow rollers.

The brush grate is particularly close-meshed, creating a smooth surface and allowing the AGVs rollers to travel evenly over the cleaning field with little vibration.

Profilgate Accesories

In addition to the high-quality ProfiGate® series, there is also a range of accessory products. With our lifting hooks, lifters, ramps and dry zones or AGV guide rails, you can not only simplify your everyday life, but also extend the function of your clean driving zones.

Lifter

The ProfiGate® lifter enables the grates to be removed quickly for cleaning purposes by just one person, without straining your back. This saves personnel costs and further minimises the already low maintenance effort. The lifter is available in a powder-coated version or completely made of stainless steel.

Long Lifting Hooks

Two long lifting hooks enable back-friendly removal of the gratings from the trays. Removal is carried out by two people.

Cleaning Panel

ProfilGate® is extremely low-maintenance, but even the best system needs to be cleaned from time to time. We provide our customers with cleaning boards free of charge for this purpose. These explain correct and safe cleaning in pictures and there are interchangeable plans in which the service teams can document the cleaning.

Dosing Station

The ProfilGate stainless steel dosing station enables automatic filling of the disinfection trays. The time and filling duration can be set individually (24/7) via the integrated Siemens logo control.

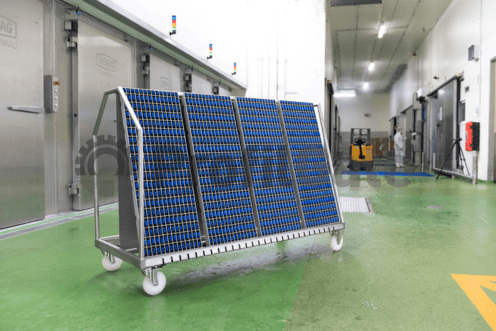

Transport Trolley

With the help of the stainless steel transport and cleaning trolley, daily cleaning can be carried out more quickly and more efficiently. Up to 8 graties can be transported on the trolley at the same time.

Dryzone Series b

The use of the ProfilGate® Dryzone series b can greatly minimise the introduction of moisture. The Drypads absorb moisture as well as oil and grease from the treads and transfer it to the VA trays via the perforated plate. The system is compatible with most ProfilGate® segments and can therefore also be retrofitted.

Pedestrian Ramp (short)

The short pedestrian ramps are special ramps for the ProfilGate® go series. With a depth of 250mm 9.84″, they take up very little space, but are not suitable for driving over due to their gradient.

Vehicle Ramp (long)

The long access and exit ramps enable ProfilGate® clean driving zones to be used above ground for test purposes or as a temporary solution.

Fixing Bracket yellow

The fixing brackets are used to fix the trays laterally when used above ground. At the same time, they limit the travel path.

VA Fixing Bracket

The VA fixing brackets are used to fix the segments laterally when used above ground. They are used at the edges of two VA trays.

AGV Guide Rails

The AGV guide rails enable ProfilGate® clean driving zones to be easily retrofitted for use with automated guided vehicles (AGVs) that navigate along a floor marking.

Dryzone Basic

The ProfilGate® Dryzone basic minimizes the introduction of moisture from wheels and tires. It can be easily placed behind the ProfilGate® cleaning zones. Wheels and tires are first thoroughly cleaned and then dried. The mat can be individually adjusted in length and width and can be used on most floor coverings such as concrete, vinyl tiles or linoleum.

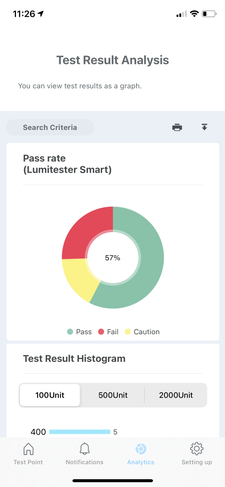

Exportable Data and Reports for Regulatory Compliance

Exportable Data and Reports for Regulatory Compliance

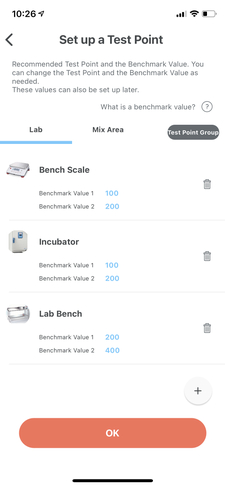

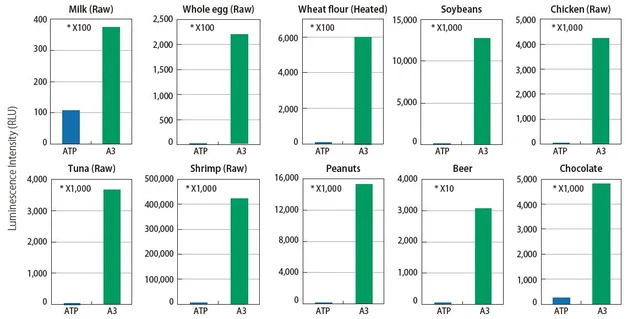

See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t